The shopping centre had damaged poly grease traps due to flood groundwater pressure.

Temporary fencing installed for safety, concrete cutting, removal and excavation of the damaged grease traps.

Excavation is slow going as only small machinery can be used due to the low height clearance. And extra time to remove excess groundwater from the hole

The concrete Grease Traps arrive on site.

Low ceiling height and poor access meant installation of two 1500 Litre Grease Traps to gain the required total volume of 3000 Litres.

Concrete lids weighing 750kg withstand all traffic. Access lids for cleaning of the grease traps

A Manitou moves the grease traps to the hole and drops them into position.

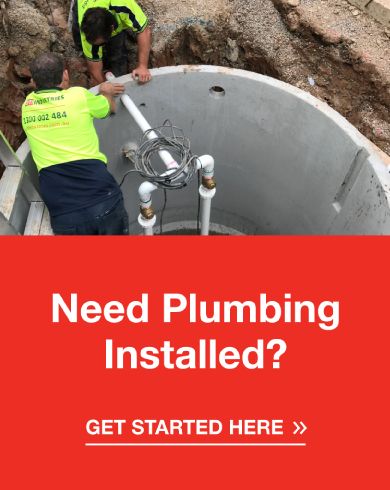

Plumbing pipes connected between each grease trap and the sewerage system

Stabilising sand arrives and the bobcat transfers it to the site to be backfilled around grease traps which sets adding strength to withstand any future groundwater pressure

Soil is replaced into the excavation hole. Then levelled and compacted getting ready for concreting

Due to no access, concrete trucks were parked 100 metres away and concrete pumped all the way to the install site around the grease traps securing them into position, and made level with the existing concrete in the car park.

After concrete sets, next is site tidy up,

And the grease traps will work away silently allowing the supermarket and shopping centre to continue business as usual.